10 Essential Tips for Choosing the Right Laser Tube for Your Project?

Choosing the right laser tube can be a daunting task. Each project has unique requirements, and finding the perfect fit is essential. According to John Smith, a renowned expert in the laser tube industry, “Selecting the right laser tube is crucial for achieving the desired results.” Understanding the specifics of laser tubes can make all the difference.

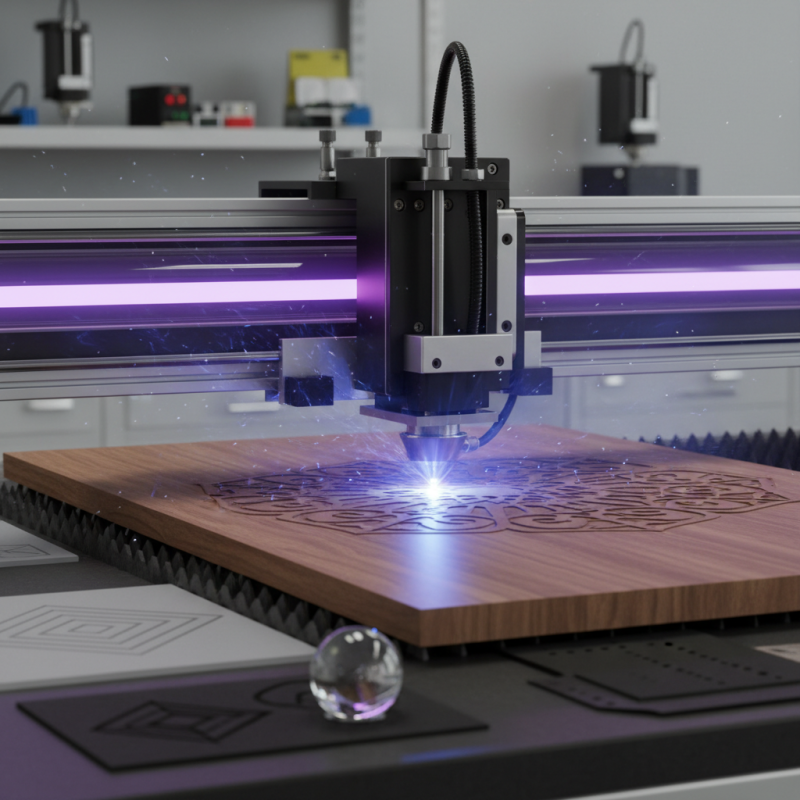

Laser tubes come in various types and sizes, each suited for different applications. For instance, CO2 laser tubes are widely used for cutting and engraving materials like wood, acrylic, and glass. However, not all CO2 tubes are created equal. You might find some that perform exceptionally well, while others may underdeliver. This discrepancy can lead to frustration and wasted resources.

It's important to consider the power output and beam quality of the laser tube as well. A poorly chosen laser tube can lead to issues that compromise project quality. Evaluating manufacturer specifications is essential. Yet, many overlook these details. Navigating these choices can feel overwhelming. But taking the time to reflect on your project's needs can yield significant benefits.

Understanding Laser Tube Types and Their Applications in Projects

When selecting a laser tube for your project, understanding different types can greatly enhance your results. There are CO2 tubes, fiber tubes, and solid-state lasers. Each type has its unique strengths. For example, CO2 tubes work well with non-metal materials, while fiber tubes excel with metals.

Consider the power output needed for your application. Knowing the thickness of materials helps you choose the right wattage. Higher wattage allows for faster cutting and engraving, but may not be necessary for thinner materials. This choice can impact both your project timeline and budget.

Power isn’t everything. Quality matters too. Look for reputable suppliers with a track record of reliable products. Keep in mind that installation and maintenance might be more difficult with certain tubes. Assess your skills before making a final choice. Testing different types can reveal unexpected challenges. It's essential to reflect on your project needs and make adjustments as necessary.

10 Essential Tips for Choosing the Right Laser Tube for Your Project

| Tip | Description | Suitable Materials | Power Rating (W) | Typical Applications |

|---|---|---|---|---|

| 1. Consider Tube Type | Choose between CO2, fiber, or solid-state depending on your project needs. | Acrylic, Wood, Metal | 30-150 | Engraving, Cutting |

| 2. Check Power Requirements | Assess the wattage needed for your materials and desired speed. | Glass, Paper | 40-200 | Cutting, Marking |

| 3. Evaluate Beam Quality | Consider the beam focus and quality for precision cutting and engraving. | Soft Metals, Plastics | 20-100 | High-Precision Cuts |

| 4. Assess Duty Cycle | Consider how often the tube will be used and for how long at a time. | Various | 50-300 | Continuous Production |

| 5. Look at Cooling Systems | Ensure an adequate cooling system to prolong tube life. | Metal, Wood | 40-150 | Long Operations |

| 6. Check Length and Size | Measure the space available for installation and operation. | N/A | 50-200 | Various Projects |

| 7. Review Lenses and Optics | Better lenses can improve cut quality and efficiency. | Wood, Acrylic | 30-150 | Engraving Detail |

| 8. Consider Brand Reputation | Research user feedback and reviews for quality and support. | N/A | 40-250 | Various |

| 9. Budget Appropriately | Balance between quality and cost to avoid future expenses. | Metal, Wood | 25-200 | Cost-Effective Solutions |

| 10. Verify Warranty and Support | Check warranty terms and customer support services available. | N/A | 30-100 | Post-Purchase Assurance |

Evaluating Power Requirements Based on Material Thickness for Cutting

When evaluating power requirements for a laser tube, consider the thickness of the material you intend to cut. Thicker materials demand higher power levels to achieve clean cuts. A 1/4-inch piece of wood may require around 40 watts, while a material that's 1-inch thick might need 80 watts or more. This ensures the laser penetrates effectively without wasting time or energy.

An important aspect to remember is that cutting speed also plays a role. Slower cuts on thicker materials might yield better results, but they can also lead to overheating. It's essential to strike a balance. Experiment with various settings to find the sweet spot for your specific project. Don't forget that performance can vary with different materials and their properties.

Sometimes, even with the right power, unexpected challenges arise. You might encounter issues like melting or burning, which can ruin the finish. It’s crucial to test before committing to large cuts. Understanding these nuances can save time and frustration in the long run. Reflecting on past projects and adjusting your approach can lead to improved outcomes in future endeavors.

Analyzing Wave Length Differences for Optimal Material Compatibility

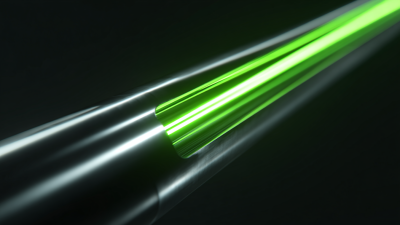

Choosing the right laser tube for your project involves many factors, especially wavelength. The wavelength of a laser influences how well it interacts with different materials. For instance, CO2 lasers generally emit light at a wavelength of 10.6 micrometers. This is great for cutting acrylic and wood. Yet, it may not perform as well on metals.

Different materials absorb various wavelengths differently. A fiber laser, with a wavelength of 1.06 micrometers, excels in cutting metals. However, it struggles with non-metallic materials like plastics. Knowing this helps in optimizing your setup for material compatibility. Sometimes, mistakes happen. A wrong choice can lead to poor results, wasting both time and resources.

Consider the thickness of the material as well. Thicker materials require specific wavelengths and higher power. If you're unsure, testing with spare pieces might help. It allows you to see how different wavelengths affect your chosen materials. This approach can provide deeper insights into the capabilities and limitations of your laser tube selection.

Wave Length Differences for Material Compatibility

Assessing Durability and Lifespan of Different Laser Tube Materials

When choosing a laser tube, material durability and lifespan are critical factors. Laser tubes commonly use glass, metal, and ceramics. Each material offers distinct advantages and disadvantages. Glass tubes are popular due to their cost-effectiveness. However, they typically have a lifespan of 1,000 to 2,000 hours. In contrast, metal tubes can last up to 10,000 hours, making them a better long-term investment.

Ceramic tubes, while less common, provide excellent thermal stability. They can withstand high temperatures without degrading quickly. However, their initial cost is often higher. A study noted that metal and ceramic tubes have lower failure rates than glass. Approximately 30% of glass tubes fail within the first year of use. This highlights the importance of material choice in project longevity.

Potential users must also consider applications. High-accuracy tasks may require more durable materials. If a project demands frequent use, investing in a higher-quality metal or ceramic tube might prevent future expenses. Balancing upfront costs with potential longevity can be challenging. Users should carefully evaluate their needs before making a decision.

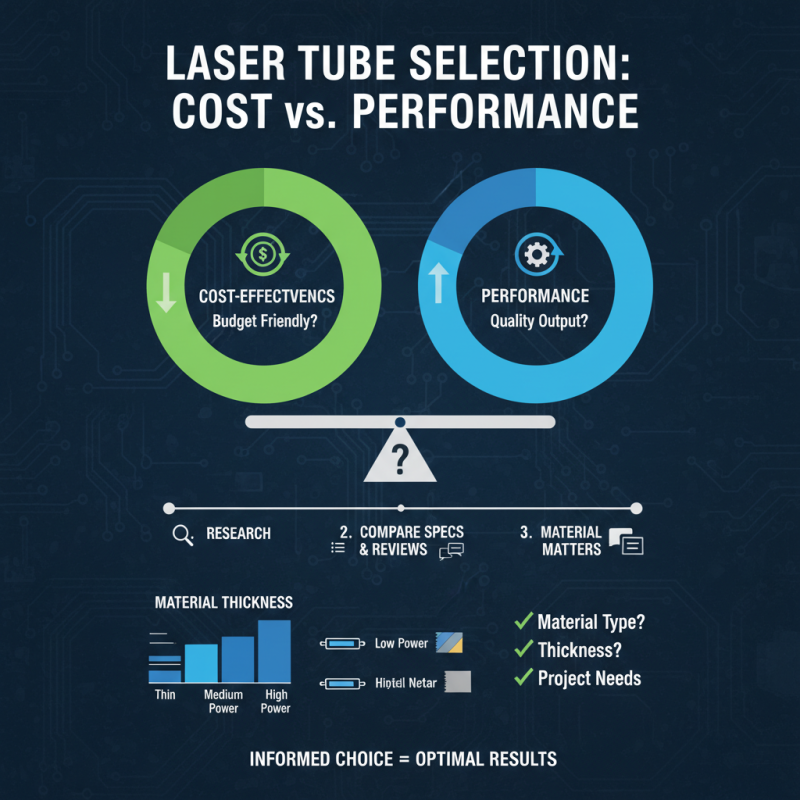

Comparing Cost-Effectiveness and Performance in Laser Tube Selection

When selecting a laser tube for your project, cost-effectiveness is crucial. Sometimes, a lower price might suggest inferior performance. However, not every expensive option ensures better quality. Assessing both cost and functionality can be a tricky balance. Research is vital. Compare specifications and user reviews, but don't overlook the specifics. What materials will you work with? What thickness are they? These details directly influence your choice.

Performance hinges on efficiency and reliability. Laser tubes need to remain consistent under pressure. A machine that falters can lead to wasted materials. Use cases vary, and the wrong tube can slow production. It's wise to pilot test different tubes if possible. Observe how they handle your specific requirements. Address any potential shortcomings early on to avoid costly errors later. Reflect on your priorities. Cost may save today, but performance ensures sustainability tomorrow. You might find better results by spending a bit more upfront.

Related Posts

-

The Ultimate Guide to Choosing the Right Laser Tube for Your Engraving Projects

-

Exploring the Future: How Laser Machines Are Revolutionizing Modern Manufacturing Techniques

-

How to Choose the Right Laser Machine for Your Business Needs

-

What is CNC Fiber Laser Cutting Machine and How Does It Work

-

2025 How to Choose the Best Tube Laser Machine for Your Business Needs

-

What is a CNC Laser Cutter? Benefits, Uses, and How It Works Explained

Machine models and specifications are subject to change without notice.