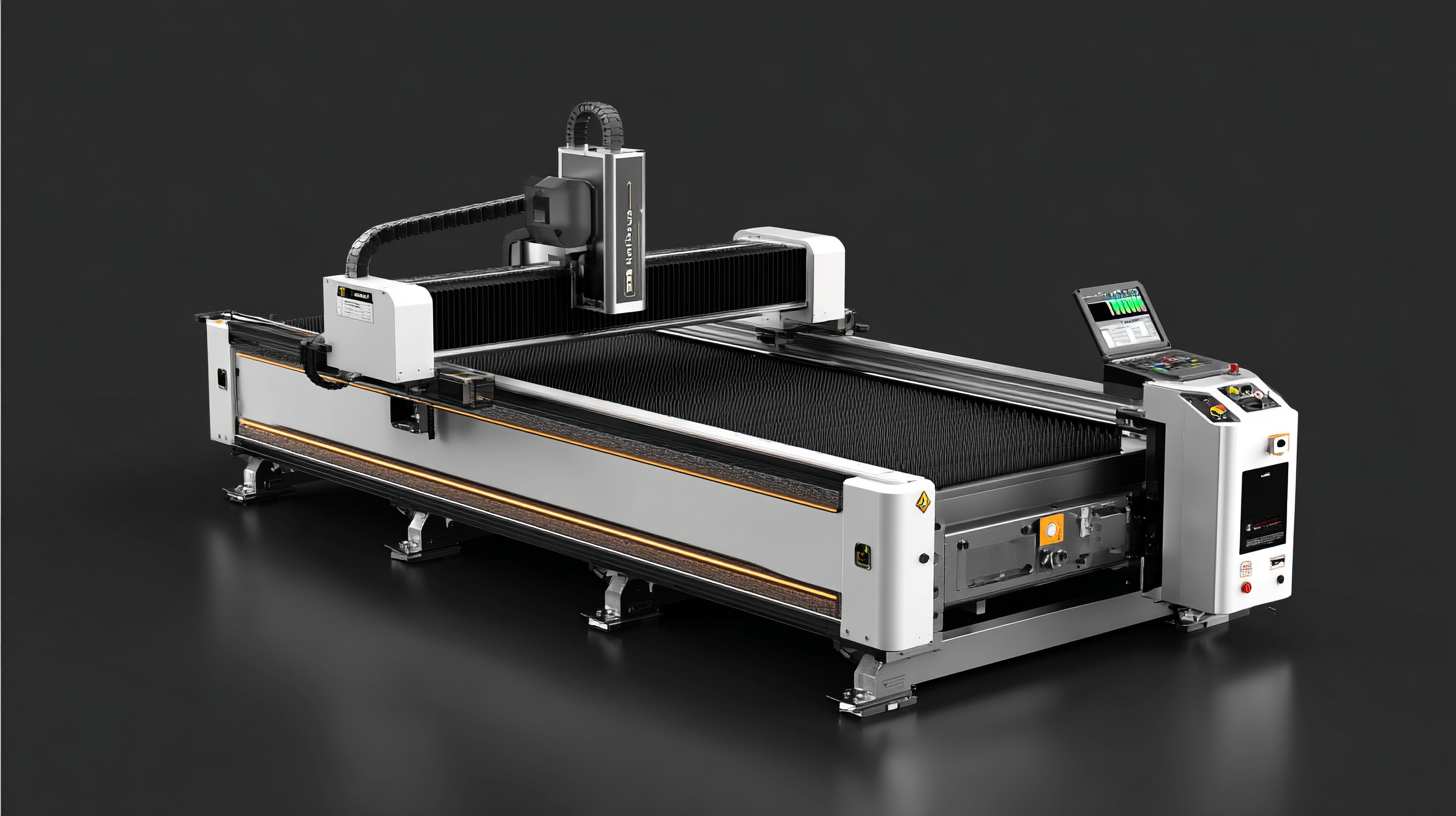

Top 5 Reasons to Invest in a CNC Laser Cutter for Your Business

In today's competitive manufacturing landscape, investing in advanced technology is essential for businesses aiming to enhance productivity and maintain a competitive edge. One such technology that has gained significant traction is the CNC laser cutter. According to a report by MarketsandMarkets, the global CNC laser cutting machine market is projected to reach USD 9.18 billion by 2025, growing at a CAGR of 6.6% from 2020. This surge can be attributed to the increasing demand for precision cutting in various industries, including automotive, aerospace, and electronics.

CNC laser cutters offer unparalleled benefits, including enhanced efficiency, versatility, and precision in cutting materials ranging from metals to plastics. A recent survey by TechRepublic indicates that nearly 72% of manufacturers that have implemented CNC laser technology have reported significant improvements in their production processes, such as reduced waste and increased operational speed. Given these compelling statistics, it becomes clear that integrating a CNC laser cutter into your business operations not only streamlines your production capabilities but also positions your company for future growth in a rapidly evolving marketplace.

Benefits of Precision: How CNC Laser Cutters Improve Product Quality

Investing in a CNC laser cutter can significantly enhance product quality by ensuring exceptional precision in manufacturing processes. According to a report from the International Journal of Advanced Manufacturing Technology, CNC laser cutting offers accuracy levels up to ±0.1 mm, which traditional cutting methods struggle to achieve. This level of precision allows businesses to produce intricate designs and components that meet stringent industry standards, ultimately leading to a competitive edge in the market.

Moreover, the versatility of CNC laser cutters enables the processing of various materials, including metals, plastics, and wood, without compromising on quality. A study conducted by Technavio indicates that the global CNC laser cutting machine market is projected to grow by over 20% by 2025, fueled by the increased demand for high-quality production and manufacturing efficiency. Companies that leverage this technology not only improve their product quality but also minimize waste, as laser cutting generates less scrap compared to traditional methods. This efficiency translates to better resource management and cost-effectiveness, further amplifying the benefits of investing in a CNC laser cutter for businesses looking to elevate their production capabilities.

Top 5 Reasons to Invest in a CNC Laser Cutter for Your Business

This chart illustrates the top five benefits of investing in a CNC laser cutter for your business, showcasing the percentage impact each benefit can provide. Improved precision tops the list, significantly enhancing product quality and service efficiency.

Enhancing Efficiency: Time-Saving Advantages of CNC Laser Cutters

In today's fast-paced manufacturing landscape, enhancing efficiency is paramount.

CNC laser cutters are leading the charge in revolutionizing production processes by significantly reducing operational time.

According to a report by the International Federation of Robotics, businesses utilizing CNC technology can achieve a remarkable

30% reduction in production time compared to traditional cutting methods.

This time-saving advantage allows companies to meet tight deadlines and increase throughput, which is crucial in today’s competitive market.

CNC laser cutters are leading the charge in revolutionizing production processes by significantly reducing operational time.

According to a report by the International Federation of Robotics, businesses utilizing CNC technology can achieve a remarkable

30% reduction in production time compared to traditional cutting methods.

This time-saving advantage allows companies to meet tight deadlines and increase throughput, which is crucial in today’s competitive market.

Moreover, CNC laser cutters eliminate the need for multiple cutting tools, streamlining workflows. A study from the Laser Institute of America indicates that laser cutting can enhance precision while reducing material waste by up to 20%. The ability to perform complex cuts with just one machine not only saves time but also minimizes the risk of errors, further enhancing productivity. As businesses strive for operational excellence, investing in a CNC laser cutter becomes not just a smart move, but an essential strategy for staying ahead in a rapidly evolving industry.

Cost-Effective Production: Long-Term Savings with CNC Laser Technology

Investing in a CNC laser cutter can significantly enhance cost-effective production for businesses across various industries. According to a report by IBISWorld, the laser cutting industry has experienced a growth rate of 3.8% annually over the past five years. This trajectory highlights the increasing adoption of CNC laser technology due to its efficiency and precision in manufacturing processes. The upfront investment may seem substantial, but the long-term savings are substantial as laser cutters can operate with lower energy consumption compared to traditional cutting methods, reducing operational costs.

Furthermore, CNC laser cutting minimizes material wastage, which is a crucial factor for businesses aiming to improve their bottom line. According to a study by MarketsandMarkets, adopting advanced manufacturing technologies like CNC laser cutting can lead to a 30% reduction in material costs. The precision of laser cutting ensures that materials are used optimally, allowing companies to maximize their resources and minimize excess spending. As industries continue to focus on sustainability and cost efficiency, the integration of CNC laser technology is becoming increasingly advantageous, ensuring not only competitive pricing but also a favorable position in the market.

Versatility in Materials: CNC Laser Cutters and Their Wide Range of Applications

CNC laser cutters are revolutionizing the manufacturing landscape due to their remarkable versatility in handling a wide range of materials. These machines can cut through metals, plastics, wood, and even fabrics with precision and efficiency. This versatility not only allows businesses to expand their service offerings but also enables them to tap into new markets. For instance, a CNC laser cutter can be used for intricate designs in metal fabrication as well as in creative art projects, showcasing its adaptability across different industries.

When considering investing in a CNC laser cutter, it's essential to evaluate the types of materials your business will be working with and how the machine's capabilities can support those needs. Tips for maximizing your investment include regularly updating your software to ensure compatibility with new materials and exploring different laser technologies to find the best fit for your projects. Additionally, investing in training for your operators can lead to better utilization of the machine, pushing the boundaries of what your business can achieve.

In recent years, the metal fabrication equipment market has shown significant growth, driven by advancements in technology. The flexibility of laser cutting machines has positioned them as a key player, allowing for high-quality precision and fast turnaround times. As industries increasingly demand quick production lines without sacrificing quality, adopting CNC laser cutting technology is proving to be a strategic move for businesses aiming to stay competitive.

Competitive Edge: Staying Ahead in the Industry with CNC Laser Solutions

In today’s fast-paced industrial landscape, staying ahead of the competition is crucial for business success. Investing in a CNC laser cutter can significantly enhance your operational efficiency, leading to innovative product development and faster turnaround times. These machines provide precision cutting that not only saves time but also reduces material waste, allowing businesses to offer high-quality products at competitive prices.

Tip: When considering CNC laser cutters, assess your business needs thoroughly. Choose a machine that can handle the materials and thickness relevant to your projects, ensuring optimal performance. Additionally, look for features like automated settings that can streamline operations and minimize manual intervention.

Embracing CNC laser solutions also opens the door to new market opportunities. Companies that adopt these technologies can explore custom fabrication services, which attract a broader customer base. By offering unique designs and rapid prototyping capabilities, businesses can differentiate themselves in a crowded marketplace.

Tip: Stay informed about the latest CNC laser technologies and trends. Regularly attending industry exhibitions or webinars can provide insights that help you adapt and innovate, ensuring your business not only keeps pace but thrives amidst the challenges of the industry.

Related Posts

-

Exploring the Future: How Laser Machines Are Revolutionizing Modern Manufacturing Techniques

-

Unlocking Precision in Manufacturing with Laser Marking Machines and Their Impact on Production Efficiency

-

How CNC Cutting Technology Is Revolutionizing Manufacturing: Insights and Trends for 2024

-

The Ultimate Guide to Choosing the Right Laser Tube for Your Engraving Projects

Machine models and specifications are subject to change without notice.