The Ultimate Guide to Choosing the Right Laser Tube for Your Engraving Projects

Selecting the right laser tube is crucial for achieving precision and efficiency in engraving projects, especially as the demand for high-quality, intricate designs continues to rise. According to a report by Research and Markets, the global laser engraving market is projected to reach $4.6 billion by 2027, growing at a CAGR of 5.4%. This growth underscores the importance of choosing the correct laser tube, as its performance directly impacts the quality of the finished product. Factors such as power, wavelength, and material compatibility are essential considerations that can significantly influence engraving outcomes. Therefore, understanding the specific needs of your projects and the characteristics of various laser tubes will not only help in enhancing productivity but also ensure that the engravings meet the evolving standards of excellence in the industry.

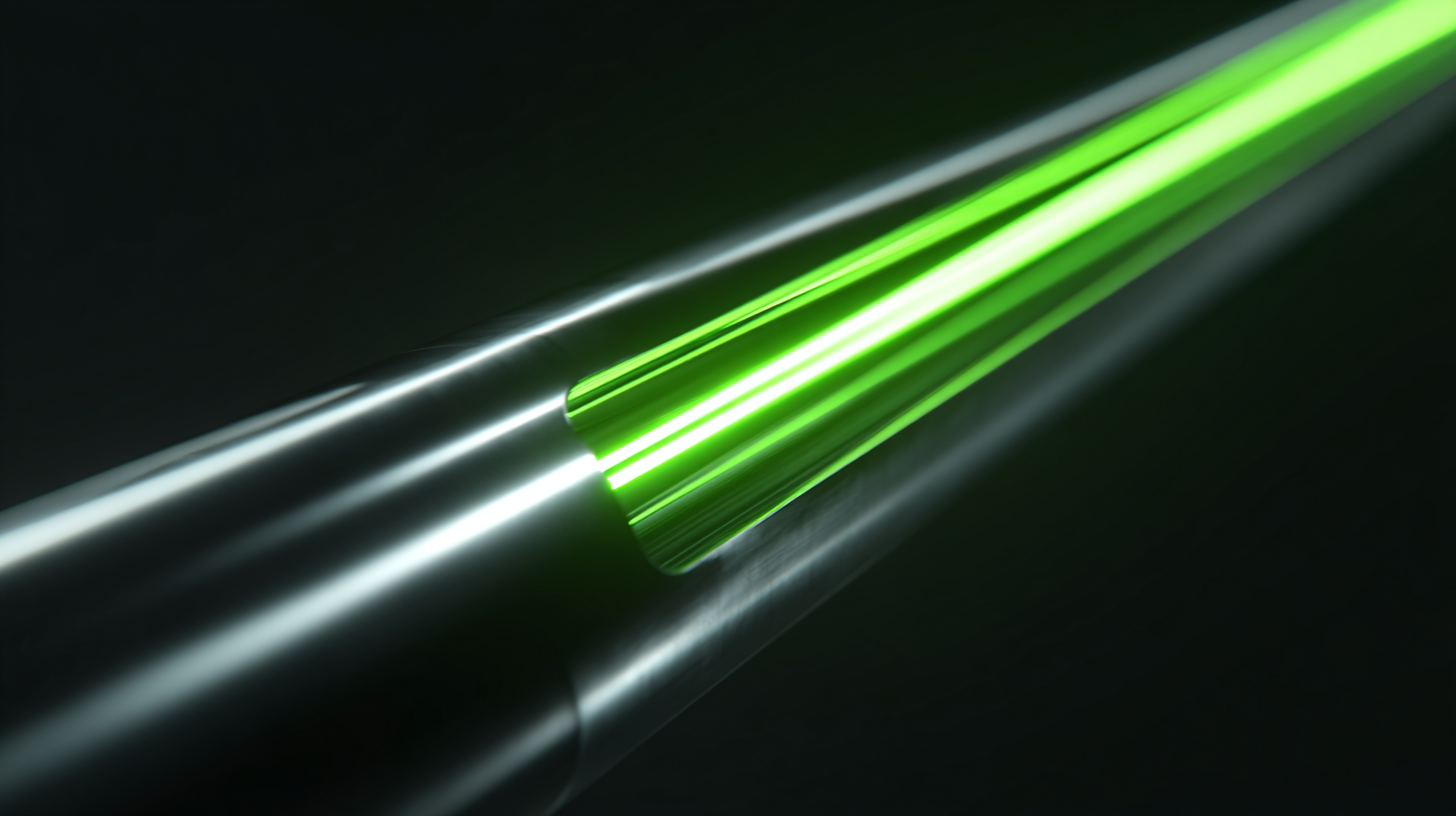

Understanding Different Types of Laser Tubes: CO2 vs. Fiber vs. YAG

When embarking on an engraving project, selecting the right laser tube is crucial for achieving the best results. There are three primary types of laser tubes to consider: CO2, Fiber, and YAG.

CO2 lasers are widely recognized for their versatility, particularly in engraving and cutting non-metal materials like wood, acrylic, and glass. They excel at creating intricate designs, making them a popular choice among hobbyists and professionals alike.

On the other hand, Fiber lasers shine when it comes to precision and speed, particularly with metals. If your projects primarily involve engraving stainless steel or aluminum, a fiber laser might be the ideal solution due to its efficiency and lower operational costs.

YAG lasers, while less common, are known for their ability to engrave on a variety of materials and are a good choice for specialized applications.

Tip: Consider the materials you plan to work with before making a decision. CO2 lasers are excellent for soft materials, while fiber lasers are best for metals, ensuring optimal performance in your engraving projects. Always check more specific requirements such as wattage and cooling systems, as they can greatly impact your engraving speed and quality.

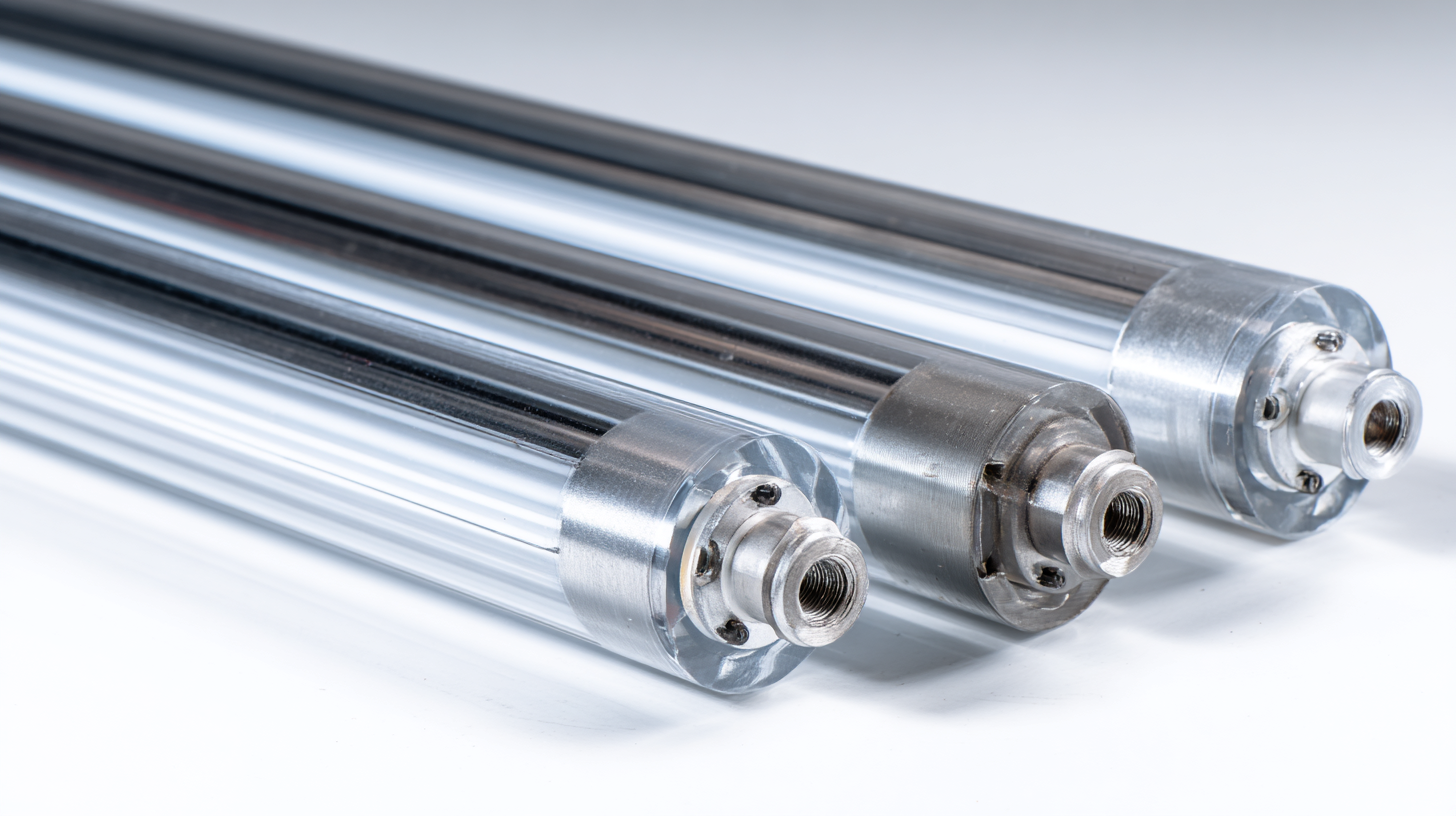

Key Specifications to Consider When Choosing a Laser Tube for Engraving

When selecting a laser tube for your engraving projects, it's essential to focus on key specifications that will directly impact performance and results. One of the most critical specifications is the wattage of the tube. Higher wattage generally translates to deeper engraving capabilities and faster processing speeds. For instance, a 60W laser tube may suffice for soft materials like wood and acrylic, while more complex projects involving harder materials may call for a 100W or higher tube.

Another key aspect to consider is the length and diameter of the tube, which can affect the beam quality and the engraving precision. A longer tube usually provides a more stable beam, while the diameter will influence the focus and the thickness of the engraving line. Additionally, the type of gas used within the tube—be it CO2 or another type—will also affect the quality of the engraving, with CO2 tubes being a popular choice for most engraving applications due to their effectiveness on a variety of materials. Always ensure to match the specifications of the laser tube with your specific project requirements to achieve optimal results.

How Wattage Affects Engraving Speed and Quality in Laser Projects

When selecting the right laser tube for your engraving projects, understanding the impact of wattage is crucial. Wattage directly influences the engraving speed and quality, making it a key factor in achieving optimal results. Generally, higher wattage allows for faster engraving, meaning you can complete projects more efficiently. For instance, a 100W laser can cut through materials like wood and acrylic much quicker than a 40W laser, significantly reducing production time for larger runs or intricate designs.

However, it’s not just about speed; wattage also affects the finish of your engravings. Higher wattage can produce cleaner, deeper engravings, enhancing the visibility and detail of your designs. Conversely, lower wattage may require multiple passes to achieve the same depth, which could lead to potential issues like burning or a rougher finish. Therefore, when choosing a laser tube, balancing wattage with your project requirements is essential to ensure that you meet both production speed and quality standards without compromising on detail.

Evaluating Lifespan and Maintenance Needs of Laser Tubes for Long-term Use

When selecting a laser tube for your engraving projects, it's essential to consider the lifespan and maintenance needs to ensure optimal performance over time. Different laser tubes come with varying lifespans, generally ranging from 1,000 to 10,000 hours. Opting for a tube with a longer lifespan can minimize replacements and downtime. Additionally, understanding the quality of components and materials used in the laser tube will also contribute to its durability.

**Tips:** Always check the manufacturer's specifications for anticipated lifespan and conduct regular visual inspections. Look for signs of wear or damage, as early detection can prevent larger issues down the line.

Proper maintenance is crucial for maximizing the lifespan of your laser tube. This includes regular cleaning of mirrors and lenses, as well as ensuring adequate cooling and ventilation. Neglecting these aspects can lead to overheating and reduced performance.

**Tips:** Create a routine maintenance schedule, and invest in high-quality cleaning supplies specifically designed for laser equipment to maintain your tube’s efficiency and longevity. Monitoring your laser tube’s performance regularly will help you identify any anomalies that may require immediate attention.

The Ultimate Guide to Choosing the Right Laser Tube for Your Engraving Projects - Evaluating Lifespan and Maintenance Needs of Laser Tubes for Long-term Use

| Laser Tube Type | Lifespan (Hours) | Maintenance Frequency | Cooling Method | Best Usage |

|---|---|---|---|---|

| CO2 Laser Tube | 2000 - 10000 | Every 3-6 Months | Water Cooling | Cutting & Engraving |

| Fiber Laser Tube | 25000 - 50000 | Annually | Air-Cooled | Metal Engraving & Cutting |

| UV Laser Tube | 5000 - 15000 | Every 6 Months | Water Cooling | Plastic & Glass Engraving |

| Diode Laser Tube | 2000 - 5000 | Every 4-6 Months | Air-Cooled | Small Engraving Projects |

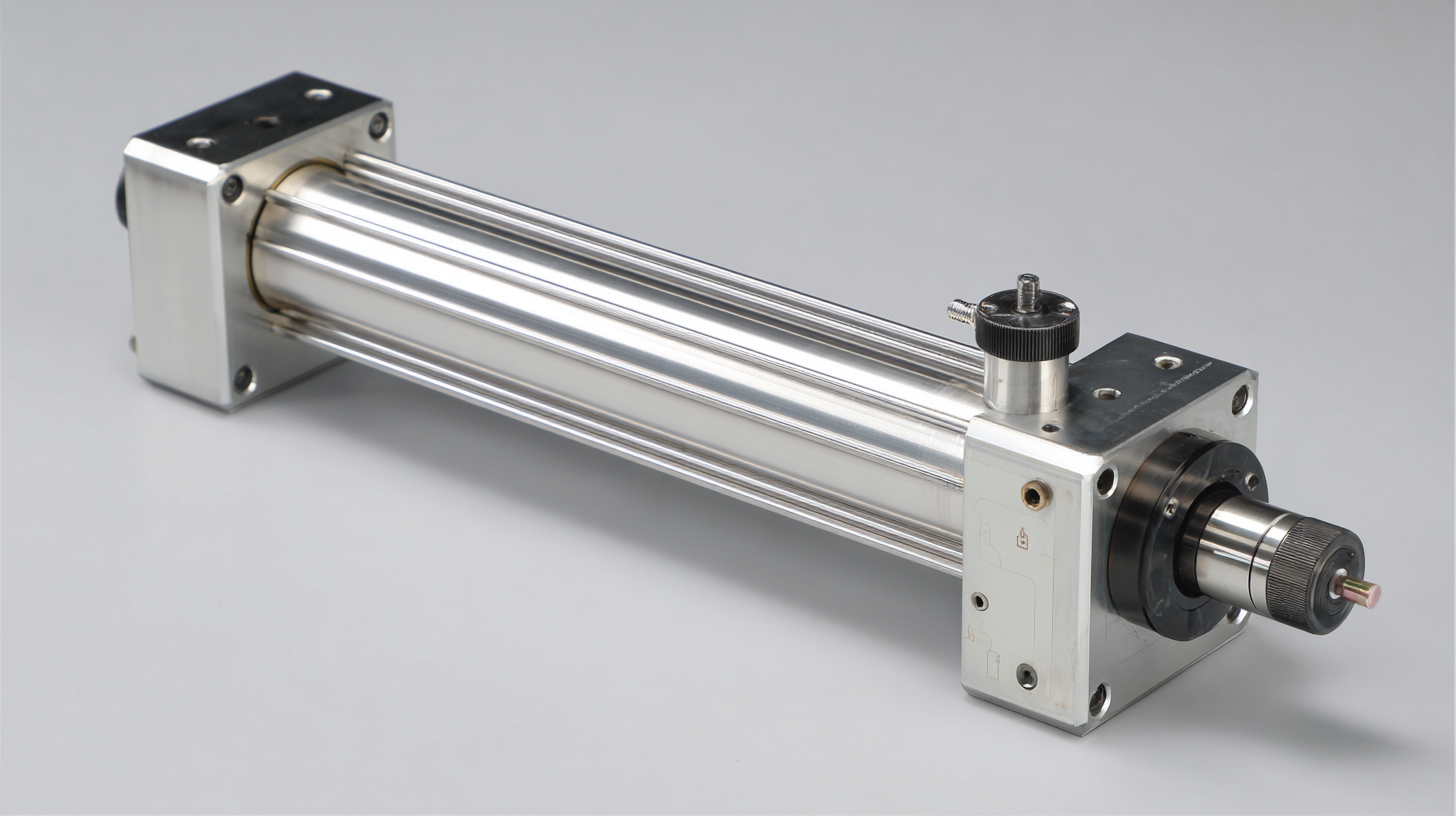

Selecting the Right Tube Size and Compatibility for Your Engraving Machine

When selecting the right laser tube for your engraving machine, understanding tube size and compatibility is crucial. The size of the tube directly affects the machine's performance and the quality of engraving. Tubes come in various lengths and diameters, and choosing the right dimensions ensures optimal fit and functionality. For instance, larger tubes typically offer more power, which can result in deeper and more precise engravings. Always check your machine's specifications to find out the maximum tube size it can accommodate.

Tips: Always measure your engraving machine's dimensions before purchasing a tube. This will prevent any compatibility issues that could hinder your workflow. Additionally, consult your machine’s manual for recommended tube specifications. Matching the wattage of the tube with the machine’s capabilities is essential to avoid overheating and damaging the parts.

In addition to size, ensure that the tube's connector types are compatible with your engraving machine. Different machines require specific connectors, and using the wrong type can lead to performance issues or even permanent damage. Comparing the tubing's electrical input and output with your machine’s requirements is a vital step in the selection process.

The Ultimate Guide to Choosing the Right Laser Tube for Your Engraving Projects

Machine models and specifications are subject to change without notice.